To understand what causes membrane fouling in ro system , we have to dive into the details about what actually is membrane fouling ? Then thereafter we will proceed to know the causes behind it in details.

The Commercial ro plant is the best commercial ro plant manufacturer in all over the india.

What actually is Membrane Fouling that occurs in RO Systems?

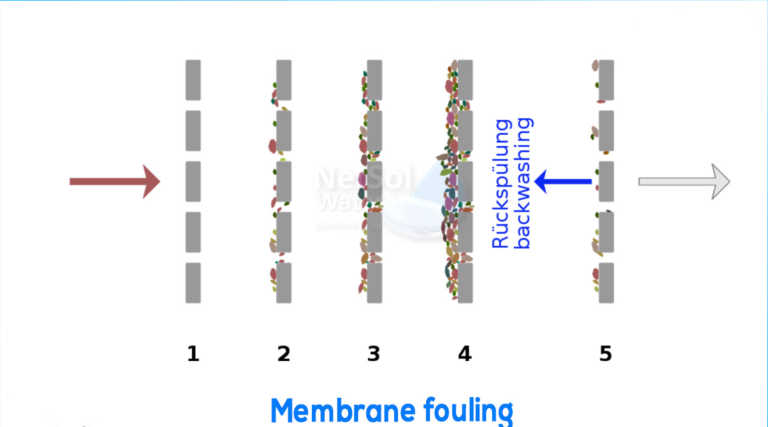

Membrane fouling happens when impurities amass on the membrane’s surface or in the membrane feeding spacer , obstructing liquid flow through the membrane. The operating system becomes less effective and functional as a result of fouling , which is the gradual accumulation of contributing deposits. Since membrane systems are mechanical , surface fouling is probable. The membranes eventually deteriorate due to this fouling.

By eliminating contaminated materials from the retentate (input stream), membrane filtering systems separate the treatment (filtrate) from the waste stream. The contaminants should preferably be removed from the membrane unit during a routine cleaning cycle or flushed away with the input stream. However, in certain instances, components in the bulk stream may crystallize, adsorb to the membrane, precipitate out of solution, or otherwise block the flow of permeate through the filter unit.

Main Causes of Fouling in the membranes of RO systems can be :

Suspended Solids:

In the feedwater , suspended-particles pile up on the surfaces of membrane . This hinders feeding conduits and may be especially challenging for lead membranes in a system . This can be brought on by suspended materials such silt , clay , silica , iron , manganese , and aluminum. Fixing affected membranes can be addressed with dispersants and surfactants .

Scaling :

A membrane’s surface may become very saturated with materials like calcium , barium , strontium , and other salts , which reduces the quantity of water that can permeate through the membrane and flow through the feed channel . A typical cleaning method for this is to apply an acidic solution with a low pH to the membrane. It is not very frequent , but if silica fouling does happen , it will be considerably harder to clean and call for a new , more specialized approach .

Organic Matter :

Membrane fouling can be brought on by naturally occurring organics in surface water. Coagulants (also known as flocking agents) and incompatible pretreatment chemicals are other forms of fouling besides organic fouling. Organic materials are often cleaned by using a high pH solution. There are times when a more specialist cleaning technique may be required, however this depends on the foulants present.

Biological Substances :

It’s feasible for biological matter to accumulate on the membrane’s surface, which would reduce the permeate and feed channel flows. Organic slimes and microorganisms are two examples of fouling components. To remove biological matter, use a high pH cleaner with dispersants at high temperatures and turbulent flow rates. If there is significant bio-fouling present, overnight soaking may be required.

Issues with membrane fouling can arise gradually or unexpectedly. Early on in the process, symptoms including rising energy costs and decreasing membrane flow are frequent. More pressure is needed to push water through the membrane as foulants accumulate on its surface, potentially harming the membrane and other system parts irreparably. so these are the what causes membrane fouling in ro system.

Fouling in the commercial RO membranes can be prevented beforehand by the following strategies as:

Scheduled Cleaning

Regular cleaning with specialized chemicals can aid in preventing the accumulation of fouling pollutants on the membrane. For best results , be sure to schedule frequent cleanings.

The architecture of the reverse osmosis system and the kind of pollutants might affect the membrane cleaning methods. You can utilize the following cleaning techniques:

Mechanical Cleaning

Using physical force to guarantee that pollutants are released from the membrane and flushed out of the system is known as mechanical cleaning .

A low-pressure, high-flow pump(60 psig) is used for this. A low pH and high pH cleaning solution is typically used to target the foulant or scale on the membrane surface during the cleaning process.

Cleaning using Chemicals

Custom-formulated cleansers are used in this sort of cleaning to remove scales and particle deposits that have formed on the membrane surface. Cleaning chemicals should be selected depending on the kind of pollutants present, and techniques tailored to the individual reverse osmosis process should be supplied. Cleaning by stage is advised to avoid poor cleaning outcomes caused by insufficient flow dynamics.

Design of a System

Membrane fouling may also be avoided with good engineering and design. Many factors influence membrane fouling and have a role in the optimal operation of the system. Consider these criteria while installing a system to avoid membrane fouling.

Membrane Choice

Choose the optimum membrane for your process size and water conditions. For surface and well waters with less than 10,000 TDS, use brackish water membrane, while for seawater applications, use seawater membrane.

Other factors to consider include:

- The cleaning pH tolerance range

- Specification for salt rejection is necessary.

- Flux rate rating to meet process needs

- Working Conditions

pH, temperature, operating pressure, and flow rate are all factors that must be balanced in a well-designed system. This enhances the likelihood that fouling pollutants will not accumulate on the membrane surface.

The most reliable the most trusted manufacturer and a consultancy venture Netsol Water provides a grand solution for almost most of the problems regarding water , and waste water treatments along with the pre- treatment and maintenance services to the users. The company NetSol Water show cases of a wide variety of its manufacturing in the segment of commercial Reverse Osmosis(RO) plant , industrial RO plant , Sewage Treatment Plant(STP) , Water Softener Plant , & Effluent Treatment Plant(ETP) , Ozonation Plant etc,.